Periodic Inspection and Testing of Hot Water and Steam Boilers

Portfolio for: Periodic Control Inspector

Periodic Inspection and Testing of Hot Water and Steam Boilers

As part of industrial safety practices and preventive maintenance programs, I performed periodic inspections, functional tests, and safety evaluations of hot water boilers and steam boilers, in accordance with relevant standards and legal requirements.

Applicable Standards and Guidelines:

-

TS EN 12953 – Shell boilers

-

TS EN 12828 – Heating systems in buildings – Design for water-based heating systems

-

TS EN 13445 – Unfired pressure vessels

-

Regulation on Health and Safety Requirements for the Use of Work Equipment (Turkey)

Scope of Work:

✅ Visual Inspections:

-

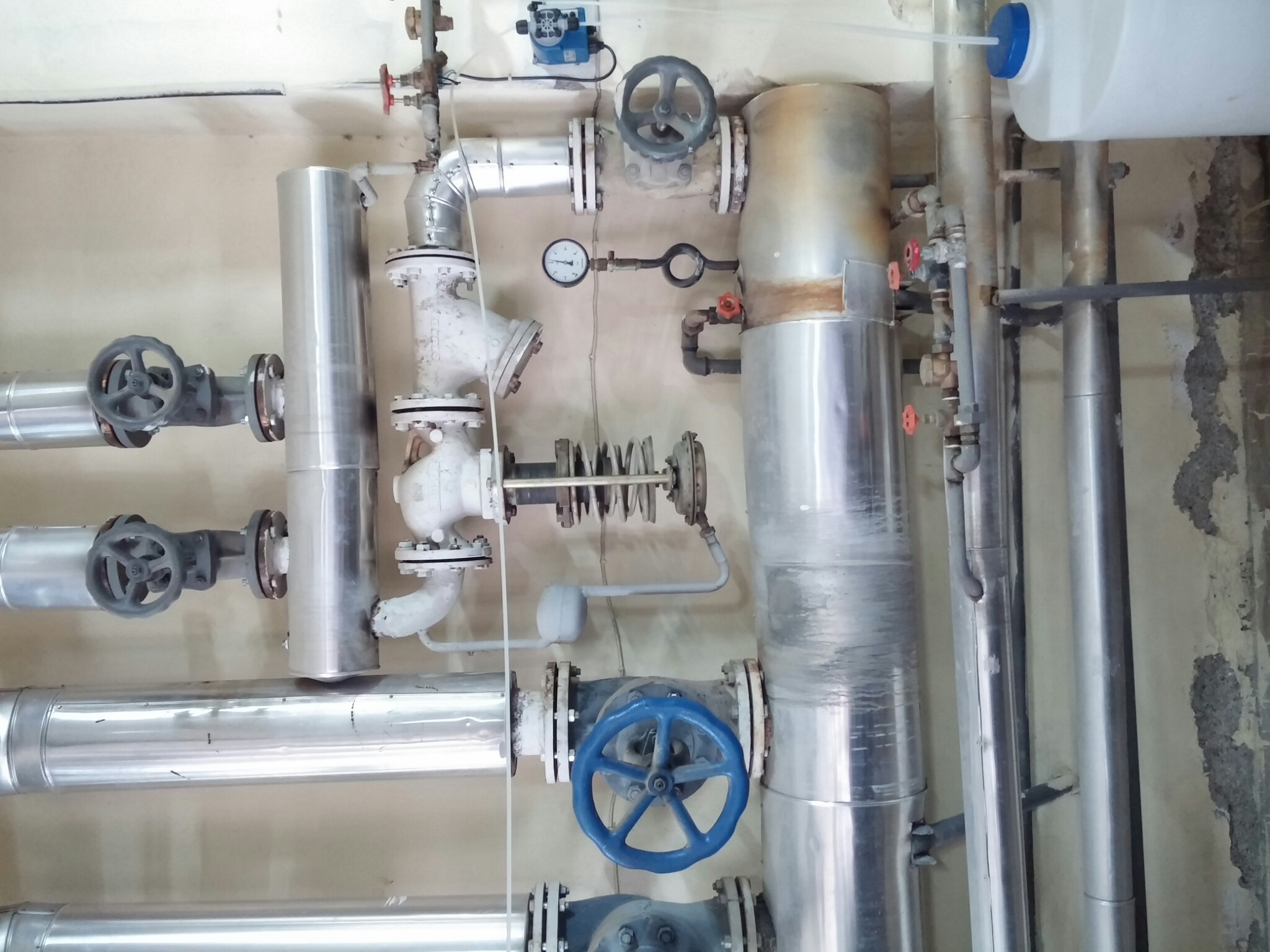

Checking for corrosion, leakage, cracks, and mechanical deformation on boiler body, piping, and connections.

-

Inspection of combustion chambers, flue gas systems, and refractory linings.

✅ Hydrostatic Pressure Testing:

-

Applied on steam and hot water boilers to assess the pressure-retaining capacity of the system.

-

Test pressures were typically set to 1.3–1.5 times the design pressure in line with regulations.

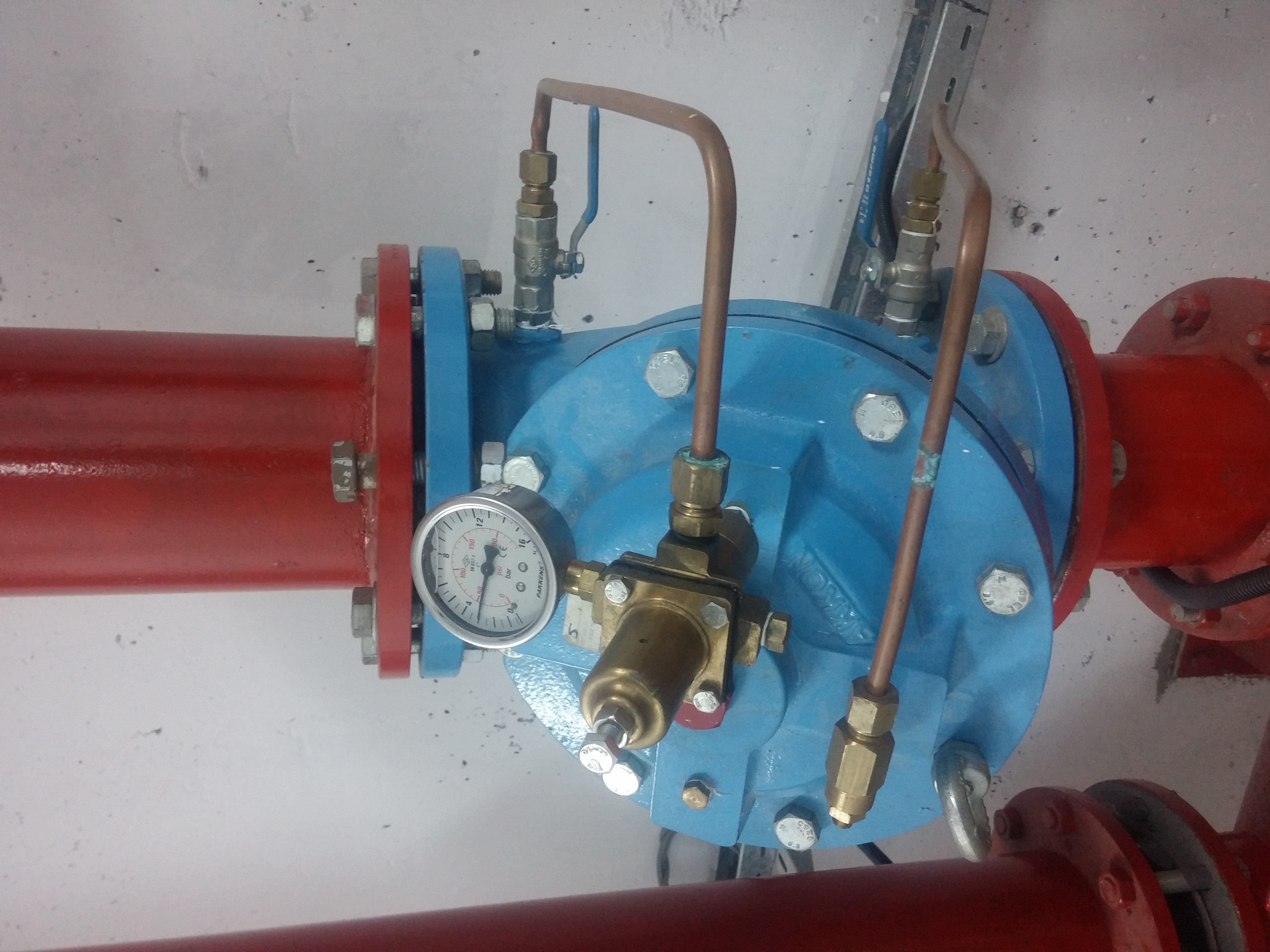

✅ Control and Safety Component Testing:

-

Safety valve functional checks (set pressure calibration, leakage testing).

-

Inspection and testing of pressure switches, level control systems, expansion vessels, and circulation pumps.

-

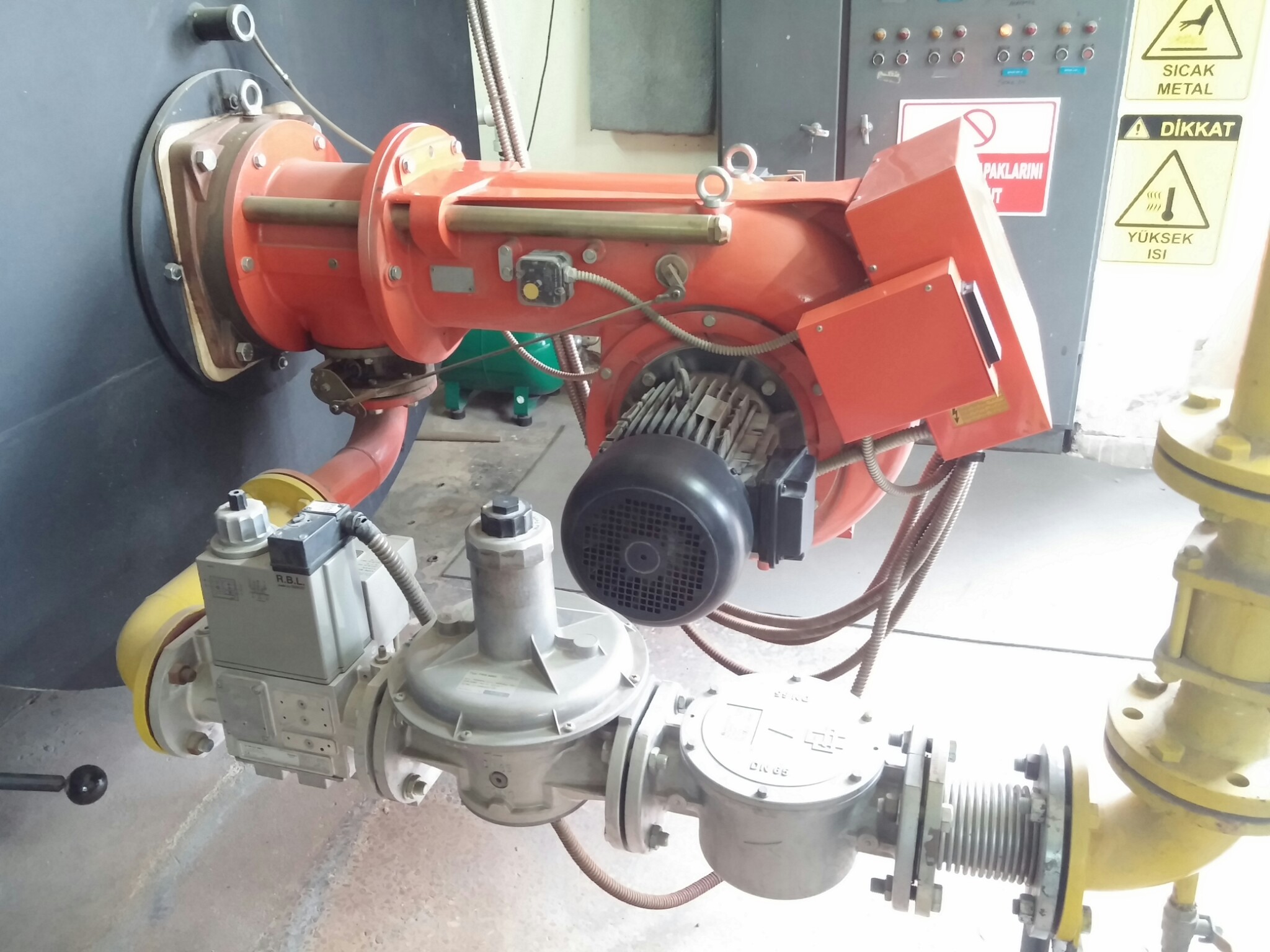

Burner operation and flame control testing for liquid and gas-fired systems.

✅ Instrumentation & Calibration Checks:

-

Verification of pressure gauges, thermometers, and temperature/pressure sensors.

✅ Documentation:

-

Preparation of detailed inspection and test reports.

-

Recording of non-conformities, follow-up actions, and re-inspection plans.

Types of Boilers Inspected:

-

Steam boilers (high and low pressure)

-

Liquid-fuel-fired and gas-fired hot water boilers

-

Condensing boilers and industrial heating units

-

Hot water systems with integrated expansion tanks and safety valves

All inspections were conducted by certified personnel using calibrated equipment, and documented in compliance with statutory requirements and quality standards.

All Periodic Inspection and Testing of Hot Water and Steam Boilers Portfolio Image